Description

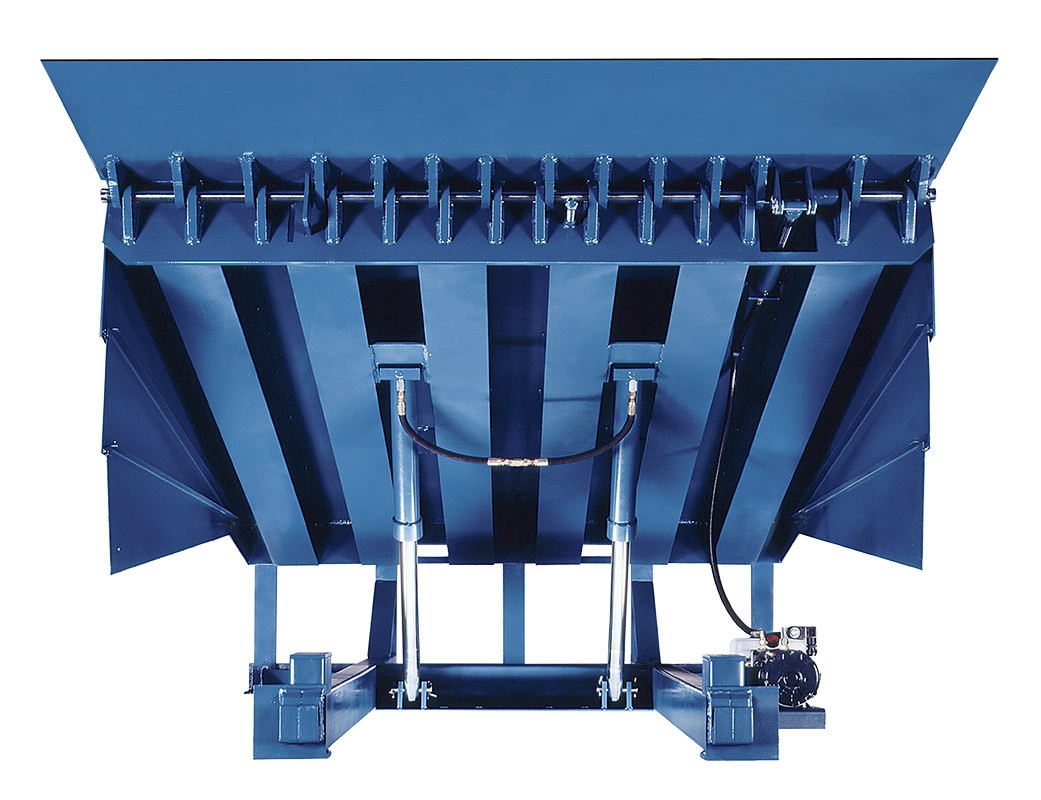

The PIT-HOOK™ Series of non-impact vehicle restraint is a recessed pit hook that stores underneath a dock pit cavity to offer unobstructed and trouble-free access to hydraulic lift gate trailers and smaller delivery vehicles.

The PH-3000 Model is a premium automatic hydraulic powered unit designed to secure a truck at the loading dock by engaging the rear impact guard with a large hook.

With a unique reach and grab functionality and equipped with HYDRA-FLOAT™ technology, the PH-3000 leaves no gap between the hook and the trailer and can easily adjust to trailer movement, virtually eliminates trailer creep and landing gear collapse.

PIT-HOOK™ Features & Benefits

- Non-Impact Vehicle Restraint Allows Unit to Mount Under Dock Pit Away from Debris

- Design Allows for Easy Snow Removal, Clean Loading Dock Appearance

- Offers Unobstructed Delivery for Hydraulic Lift Gate Trailers and Smaller Delivery Vehicles

- Exceeds 35,000 lbs. of Restraining Force

- Maintains a Tight Hold on the Rear Impact Guard Virtually Eliminating Trailer Creep

- Helps Eliminate Landing Gear Collapse by Keeping Trailer Tight to Bumpers

- Working Range of Down to 9″ Above Grade up to 30″ Above Grade

- NEMA 12 Control Box with PLC Controls

- Hook Floats with Trailer During Loading

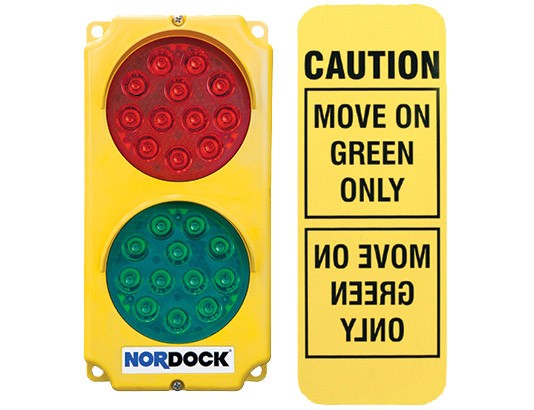

- High Visibility Inside & Outside LED Communication Lights and Signs

PIT-HOOK™ Options & Accessories

- NEMA 4 Watertight Enclosure

- Dock Leveler Stored Interlock

- LOGI-SMART® Integrated Control Systems

- Key Override Control

RECESSED VEHICLE RESTRAINT SYSTEM

DESCRIPTION

The PIT-HOOK Series recessed vehicle restraint improves safety with strength, convenience and reliability.

The PH-3000 Model is a premium automatic hydraulic powered unit designed to secure a truck at the loading dock by engaging the rear impact guard with a large hook.

The restraining hook is stored back of the building face and clear of incoming trucks within a pit cavity below the dock leveler, away from weather and debris.

The unique reach and grab aspect of the hook leaves no gap between the hook and the trailer, essentially eliminating trailer creep and preventing landing gear collapse.

The exclusive HYDRA-FLOAT hook automatically adjusts to various heights of trucks and maintains position during loading.

The operator easily activates and stores the restraining hook with the push of a button.

The hook reaches out from the stored position and holds rear impact guards as low as 9” high and rises to 30” while extending 14” horizontally to restrain all types of trailers.

OPERATION

With the exterior signal light showing green the trailer is backed into position at the loading dock until contacting the dock bumpers.

The inside light shows red until the dock attendant pushes a control button that activates the restraining hook.

The exterior signal light immediately changes to red as the hook automatically advances through its cycle until the trailer is secured.

When the hook makes positive engagement with the trailers rear impact guard the inside light will turn to green and the interlock system will allow operation of the dock leveler.

In the event a secure engagement of the trailer does not occur, an alarm will alert the operator to the fault condition.

Alternate safety procedures are required and an override control when actuated will allow operation of the dock leveler.

The hook will provide a restraining force in excess of 35,000 lbs. and will automatically adjust with trailer float during loading and unloading operations assuring the trailer is restrained at all times.

When loading or unloading is completed the dock attendant stores the restraint by pushing the release button.

The inside light immediately changes to red after the hook is fully retracted the outside light turns green signally it is safe for the trailer to leave.

CONSTRUCTION

The large solid steel hook is constructed from 50,000-PSI yield material and is painted bright yellow for high visibility. The hydraulic cylinder is constructed with high tensile micro-honed tubing, hard chrome plated rod, guide bearings, and high-pressure low-friction seals.

All hydraulic hoses are high-pressure SAE 00R2 with factory crimped fittings.

The control panel includes a NEMA 12 rated dust tight enclosure with shielded push button controls, PLC solid-state controller, communication lights and operator instructions on the cover.

All voltages are available.

INSTALLATION

The NORDOCK® PIT-HOOK Model PH-3000 vehicle restraint is factory assembled and tested before shipment.

The restraint is mounted in the pit below the dock leveler and behind the building wall.

The signs, control panel and optional components are installed in accordance to instructions contained in the installation and owners manual.

COMMUNICATION

Safety equipment includes red and green inside and outside lights with operating instructions for the dock attendant, and a large outside mounted sign with forward and reverse instructions for the truck driver.

WARRANTY

NORDOCK® guarantees that the PIT-HOOK Series vehicle restraints will perform as described and to the full satisfaction of the purchaser for One-Year from date of receipt or NORDOCK® will repair or replace the product at no charge to the purchaser.

In addition, structural and hydraulic components are guaranteed for Five-Years.

Warranties are subject to limitations on liability.