Description

The EZ-DOCK™ Series of hydraulic powered dock levelers is the smart choice for those who prefer or cannot build a conventional recessed pit in their building.

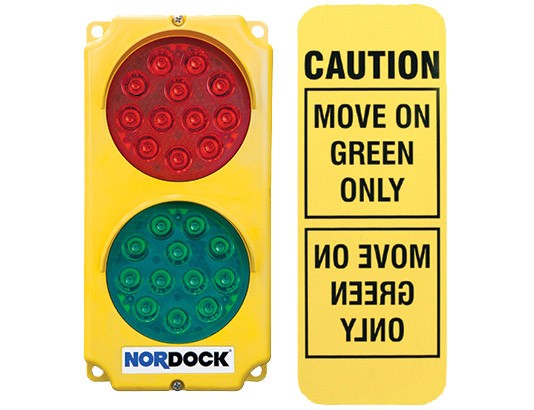

The floor-mounted design with simple push button control provides a safe and ergonomic alternative to a cumbersome, restrictive and potentially dangerous manually operated style.

SMD Features & Benefits

- Heavy-Duty Hydraulics with Patented Dual Function Activation

- Exclusive Self-Cleaning Lip Lug & Header Plate Design Ensures Maximum Strength

- Smooth Transition Continuous Fixed Rear Hinge with No Pinch, Trip or Impact Point

- Integral Lip & Deck Maintenance Supports

- Full Width Plated Front & Rear Hinge Rods

- Dual side 33% Deck to Beam Weld Pattern

- Floor Mount Approach Ramp & Door Filler Plates

- Self-Contained 1 HP Power Unit

- Single Push Button Activation

- 18” Standard Lip Length

- Security Night Locks

- Totally Enclosed Bumpers Blocks

- Heavy-Duty Dock Bumpers Included

SMD Options & Accessories

- 20” Long-Lip

- Emergency Stop Control

- 20” Laminated Bumpers & Blocks

- Wall Mounted Power Unit

- Dock Lights

- SMART-HOOK® & TRUCK-LOCK® Vehicle Restraints

- Wheel Based & PIT-HOOK™ Vehicle Restraints

- WEARTOUGH® Dock Seals & Shelters

- FALL-STOP™ Safety Barrier Gates

- IMPACT™ Series Steel Spring & Steel Face Dock Bumpers (10-Year Structural Warranty)

- LOGI-SMART™ Integrated Control Panel

DESCRIPTION

The EZ-DOCK™ Series of hydraulic powered dock levelers is the smart choice for those who prefer or cannot build a conventional recessed pit in their building.

The floor-mounted design with simple push button control provides a safe and ergonomic alternative to a cumbersome, restrictive and potentially dangerous manually operated style.

The patented lifting system utilizes a revolutionary Dual Function Cylinder that lifts the deck and extends the lip with the simple push of a button.

The self-contained design provides easy handling & installation with an integral mounted power unit and fully plumbed and tested hydraulics.

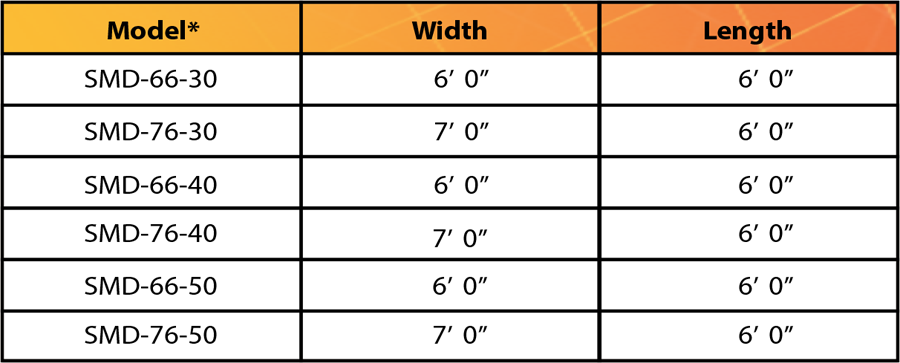

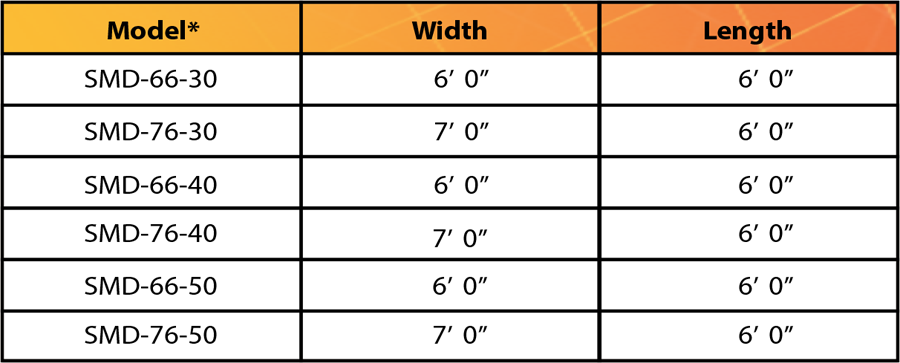

Available in 30,000, 40,000 & 50,000 lb. rated capacities and standard nominal platform sizes of 6 & 7’ wide x 6’ long including lip and ramp.

Standard features include an 18” long lip, night security locks, dust tight control panel, integral lip and deck maintenance supports, safety black & yellow side skirt labels, approach ramp, door filler plates and two heavy-duty bumpers with extension blocks. Total unit projection is 18” from building wall.

OPERATION

The operator presses the control button until the deck is raised and the lip is fully extended.

Releasing the button allows the deck to lower until the lip contacts the trailer bed.

The leveler will float up and down and side to side with the truck during loading to maintain lip contact at all times.

To store the dock leveler, the operator presses the control button activating the lift system allowing the lip to automatically retract to a pendant position, releasing the button will store the leveler in a fully supported level position.

The standard 18″ lip will extend out 11″ beyond the front face of the bumpers and engage a truck 10″ above and 6” below building floor level.

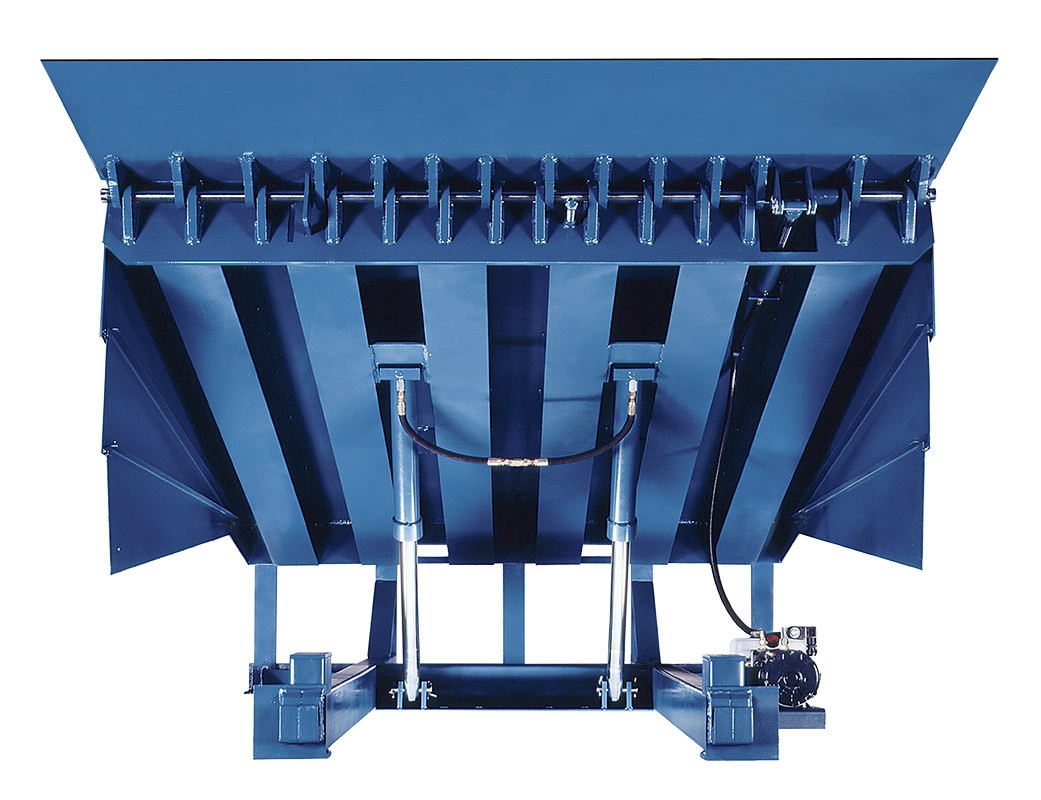

CONSTRUCTION

Unitized platform structure with dual side 33% Beam to Deck Weld pattern and continuous welds at the beam to header plate and lugs for maximum strength. The deck plate, lip plate, ramp and beams are constructed from high-tensile steel and safety tread top running surface.

The deck support structure includes structural channel beams, 55,000-PSI checker plate deck and lip for superior strength. The ramp is 4” high x 24” long with a fixed continuous smooth transition rear hinge to eliminate pinch, trip or impact point.

A security lock system prevents illegal building entry when the overhead door is closed.

Full width zinc plated front & rear hinge rods are constructed from SAE 1045 superior shaft and factory coated with anti-seize lubricant. Bumper block outs are closed on all sides with 13” high x 10” wide solid molded bumpers attached. A single NEMA 4 push-button control operates the 1 HP power unit.

WARRANTY

NORDOCK® guarantees that the SMD Model of hydraulic dock levelers will perform as described and to the full satisfaction of the purchaser

for one-year from date of receipt or NORDOCK® will repair, replace or remove the product and refund the purchase price.

In addition, the structural components are guaranteed, under specified guidelines, for a period of Ten-Years.