Description

The SMART-HOOK® AR-20K is the premium industry leading automatic vehicle restraint designed to secure virtually all trucks at the loading dock by using a large rotating hook to engage a trailer’s rear impact guard (RIG).

Featuring the patented NO-PINCH™ Auxiliary Lock System, POWER-SAFE™ Battery Reserve System and patented IMPACT-GUARD™.

The AR-20K offers the most enhanced loading dock safety and performance in the industry.

The patented NO-PINCH™ Auxiliary Lock System will not pinch the rear impact guard, providing the highest level of safety in the vehicle restraint industry.

The patented IMPACT-GUARD™ front carriage reinforcement increases front carriage strength by over 10 TIMES competing designs and protects your investment from damage caused by incoming trailers.

The POWER-SAFE™ battery reserve system supplies auto-recharging battery power to the restraint and communication lights for over 24 hours allowing you to stay safe, engaged, and in control at all times.

With maximum mounting force exceeding 100,000 pounds, AR-20K restraints are capable of holding the heaviest trucks while the locking hook secures virtually all rear impact guards in excess of 32,000 pounds of restraining force.

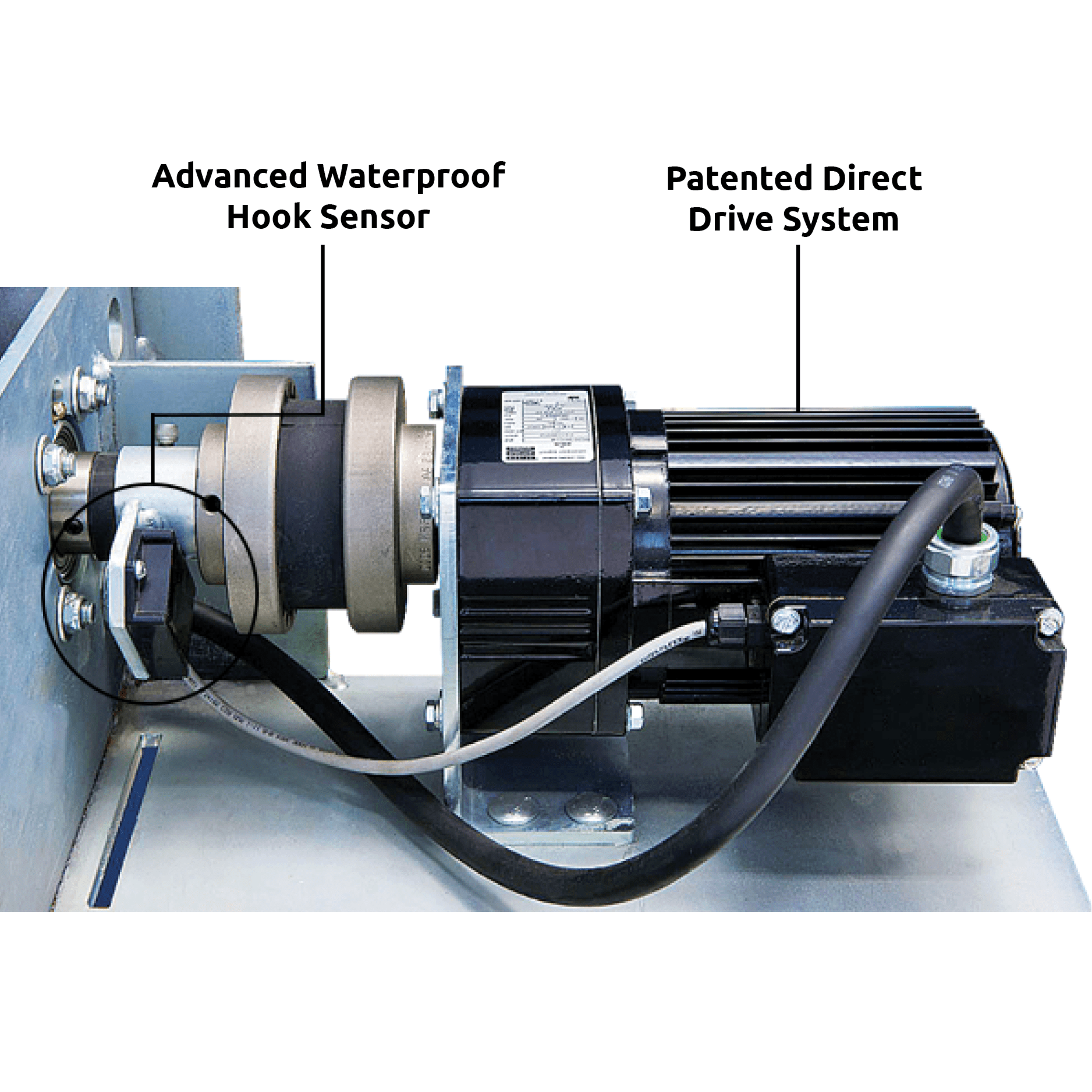

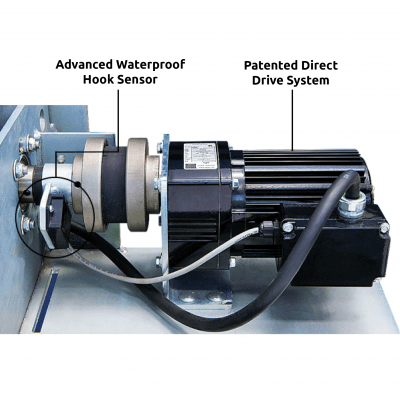

The patented Direct Drive System and Advanced Waterproof Hook Sensor replace moving parts that will fail in competing products.

Eliminating these parts substantially reduces maintenance and downtime resulting in a lower cost of ownership.

NORDOCK® has continued to evolve the SMART-HOOK® vehicle restraints to meet all the changes and challenges in the industry, by offering innovative new options to help maximize safety at your loading dock.

AR-20K Features & Benefits

- POWER-SAFE™ System Provides Full Power for Over 24 Hours, Allowing Safe Release, Engagement and Uninterrupted Inside and Outside Communication Lights

- All Functions are Automatically Reset Once Power is Restored

- Patented NO-PINCH™ Auxiliary Lock System

- IP66 Rated Waterproof Motor/Gearbox

- Patented IMPACT-GUARD™ Superior Design Eliminates Damage Caused by Trailer Impact

- Upward Biased Housing and Hook Keep Constant

- Contact with Rear Impact Guard

- Solid State Control System with Diagnostics

- Over 32,000 lbs. of Restraining Force and 100,000 lbs. of Mounting Force

- 5-Year Structural Warranty

- Large Rotating Hook Design Prevents Unscheduled Departure, Trailer Creep and Tip Over

- Patented Direct Drive System Eliminates High Maintenance Clutch, Chain and Brake Components

- Waterproof IP67 Rated Hook Position Sensor Eliminates Failure Prone Mechanical Limit Switches

- Fault Sensor Alarm Alerts Operator When A Missing or Damaged Rear Impact Guard is Detected

- Auto-Reversing Hook Avoids Damage from Incoming Truck

- NEMA 12 Control Panel with Steel Enclosure and Operator Instructions on Hinged Cover

- Above Ground Storage Provides Easy Dock Clean-Up and Keeps Housing Clear of Snow, Ice and Debris

- Low-Profile Housing Lowers to 9” Off Grade

- Dual Zinc Dichromate Finish

AR-20K Additional Options & Accessories

- Integrated LOGI-SMART® Control Systems

- Cantilever Extension Mounting Bracket

- Watertight Panel Enclosures

- Cast-In Wall Mounting Plate

- Keyed Override Switch

- SUPER-COM™ Signal Light System

Description:

The SMART-HOOK® Model AR-20K is a premium automatic vehicle restraint designed to secure trucks at the loading dock by using a large rotating hook to engage a trailer’s rear impact guard (RIG).

The AR-20K offers trouble free operation and long-term reliability with 32,000 lbs. of restraining force.

Loading dock safety is improved with the patented NO-PINCH™ auxiliary lock and POWER-SAFE™ battery reserve systems. In addition, the patented IMPACT-GUARD™ front carriage reinforcement provides unequalled protection from damage caused by incoming trailers.

Able to supply power to the vehicle restraint in the event of a power outage, the auto-recharging POWER-SAFE™ battery allows full operational restraint functions with safety communication lights for over 24 hours, keeping truck drivers and dock attendants safe, in control and on schedule.

The low profile housing automatically adjusts to various trailer heights and movement and lowers to 9” above grade, avoiding potential damage from low RIG’s.

The restraint is stored above ground level, keeping free of snow, ice and debris.

Operation:

As the driver backs the truck into the loading dock, the trailer’s RIG makes contact with the restraint housing, automatically positioning the housing under and firmly against the RIG.

With the truck in position, the driver sets the brakes and chocks the wheels.

The dock attendant pushes the lock button, activating and positioning the large rotating hook in front of the RIG, safely securing the trailer to the loading dock.

During loading/unloading, the housing automatically adjusts to the trailer’s movement while the hook positioning sensor monitors the hook and provides constant upward biased pressure against the RIG, preventing hazards such as trailer creep, early departure and/or tip over.

When no RIG is detected, the hook automatically stores away to avoid damage and goes into fault mode, sounding an alarm to alert the dock attendant.

Pushing the override button will silence the alarm while the communication lights indicate a caution condition.

Once the loading cycle is complete, the dock attendant stores the hook by pressing the release button; inside and outside lights then signal the driver and dock attendant when it is safe for the truck to leave.

Communication:

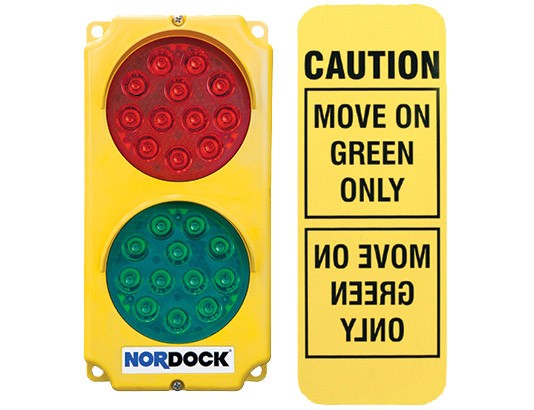

High-visibility red and green inside and outside LED lights with operator instructions on inside control panel cover and outside mounted sign with clear, large, forward and reverse lettering for drivers.

If power is lost, the inside and outside lights flash to indicate a power loss condition that is maintained until power is restored.

An audible alarm and inside red light warns dock attendant when no RIG has been detected.

Construction:

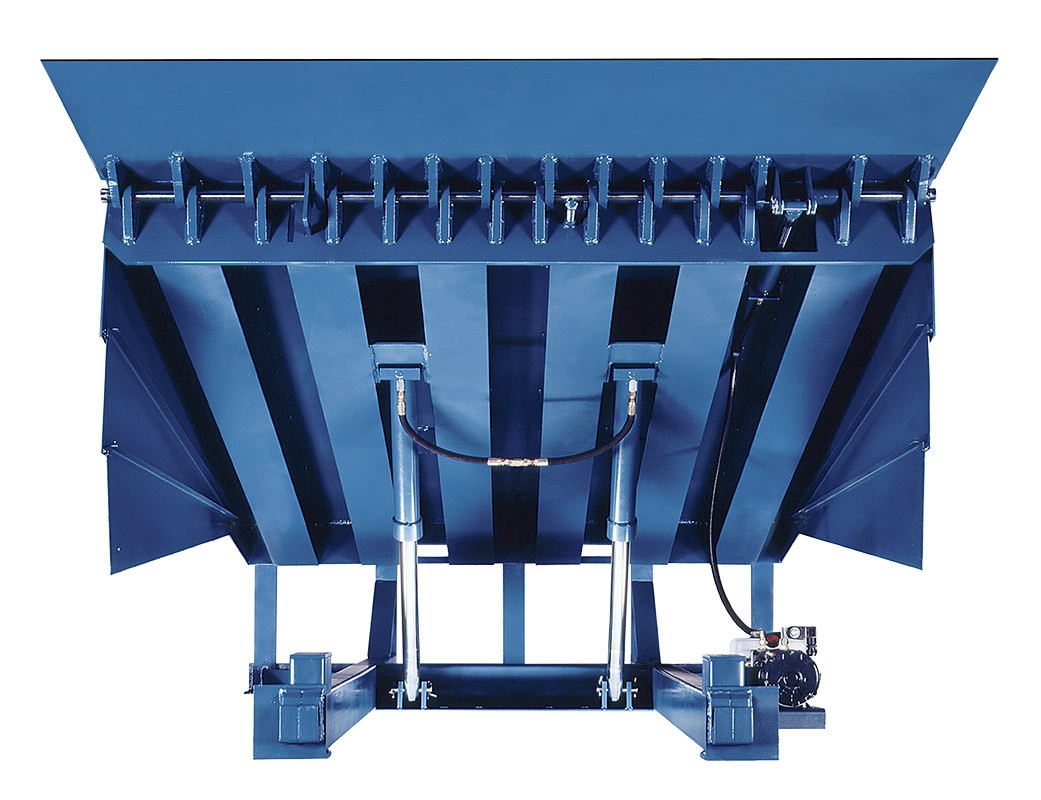

The enclosed housing design is a structural welded assembly constructed with 5/16” side plates and 1/2” high tensile reinforcement on leading edge to withstand repeated impacts from backing trailers.

The large rotating hook is constructed of 1 1/4” thick steel and is attached to the housing using a superior 1 1/4” diameter shaft.

Zinc plated components include mounting plate, track, hook, housing, and brackets.

The housing also comes with black and yellow caution markings for improved visibility.

Waterproof IP67 rated hook position sensor for trouble free non-mechanical hook monitoring.

Patented drive system consists of a direct-coupled IP66 waterproof rated high torque DC motor and high efficiency helical gears.

Control panel includes a NEMA 12 rated dust tight enclosure with push button controls and LED communication lights on the cover.

The power requirement is 120 volts, single phase and 2 amperes.

Installation:

The vehicle restraint is mounted to the dock face with concrete wall anchors (included) and then welded onto the pit curb angle.

Alternatively, the vehicle restraint can be welded onto a dock face embedded steel plate. Total mounting force is in excess of 100,000 pounds.

Signs, control panel and optional components are installed in accordance with instructions contained within the installation and owner’s manual.

WARRANTY:

One-Year parts and labor and Five-Year structural warranty from date of shipment.