Description

A fast and efficient alternative to vertical storing dock levelers.

The COLDSTORAGE™ Series of vertical and horizontal dock levelers are ideal for facilities that require strict climate control or where security is of primary concern.

Designed to store behind a loading docks insulated doors, the COLDSTORAGE™ Series of dock levelers allow the overhead dock doors to fully close down to the pit floor, creating an optimum seal for effective environmental control, cleanliness and warehouse security.

A quick and efficient alternative to vertical storing dock levelers the TLH stores horizontally for fast operation, extending its lip straight into the trailer with only a slight raise of the deck, reducing loading cycle times and improving climate control.

The TLH provides infinite end load access with precise lip control, safely bridging the gap between deck and trailer bed for forklift access and avoiding potential damage to cargo and/or forklift.

Improve sightlines, increase floor space and save money.

The TLH horizontal storing TELESCOPING-LIP™ dock leveler stores flush to the dock floor, improving driver sight lines and creating a clear open space for cross traffic operation and reduces installation costs by eliminating the need for guardrails, burying conduits, bollards and stanchions.

TLH Features & Benefits

- Full Hydraulic Powered Deck and TELESCOPING-LIP™ for Precise Lip Control and Positioning

- Quick Start-Up Operation

- Reduces Load Cycle Times

- Increases Climate Control

- Infinite End Load Access

- Flush Storing Increases Floor Space for Cross Traffic Operation

- Improves Driver Sightlines

- Inside Storage Allow Overhead Dock Doors to Close to the Pit Floor

- 12″ Above and Below Service Range

- Avoids Interference with Vehicle Restraint

- No Run-Off Guards Eliminate Impact and Damage to Forklift Tires and Improve Maneuvering

- Eliminates Costly Installation of Bollards, Stanchions and Guardrails

- Raises Vertically for Easy Clean-Out and Safe Maintenance Access

- 10-Year Structural and 20-Year Rear Hinge Warranty

TLH Options & Accessories

- 18″ or 20″ Long Lip

- Automatic Return to Dock Level

- Self-Forming Pour in Pans

- Brush & ALL-SEAL™ Weather Seal Systems

- Dock Lights

- SMART-HOOK® & TRUCK-LOCK® Vehicle Restraints

- Wheel Based & PIT-HOOK™ Vehicle Restraints

- FALL-STOP™ Safety Barrier Gates

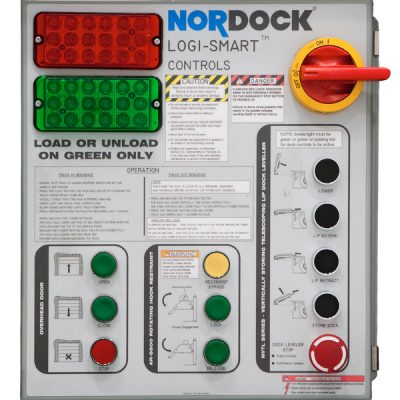

- LOGI-SMART® Integrated Control Systems

- WEARTOUGH® Dock Seals & Shelters

- IMPACT™ Series Steel Spring & Steel Face Dock Bumpers (10-Year Structural Warranty)

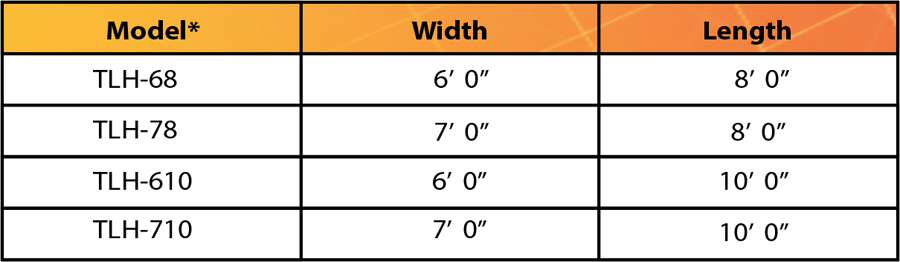

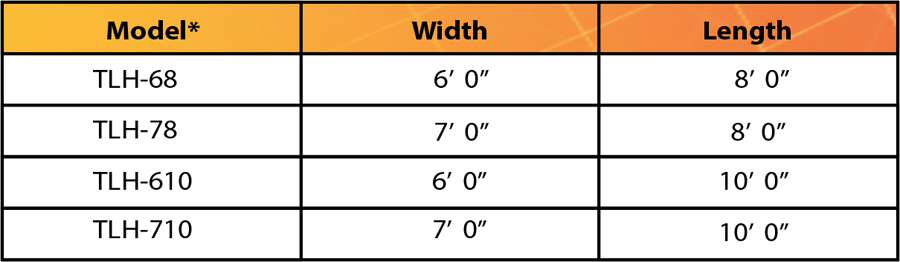

*Add capacity required from 25,000 to 65,000 lbs. Example: NV-76-40

DESCRIPTION

An effective alternative to vertical storing dock levelers the TLH model stores horizontally, extending its lip straight into the trailer with only a slight raise of the deck, for quick loading cycles and improved climate and environmental control.

Its TELESCOPING- LIP™ provides safe and precise end load access, safely bridging the gap between deck and trailer bed for smooth forklift access.

The TLH comes with a standard 20″ lip extension on 8′ units and 40″ lip extension of 10′ units and a 12″ above/below service range.

NV models are available in load capacities of 30,000 to 80,000 lbs.

OPERATION

Simple push button controls enable the operator to raise and lower the ramp as well as control the extending and retracting of the lip at any time during operation for quick cycles and end load access.

For increased safety, the operator must power the deck before the mechanical latch can be released to allow lowering.

Separate deck and lip maintenance supports are also provided for added security and convenience.

CONSTRUCTION

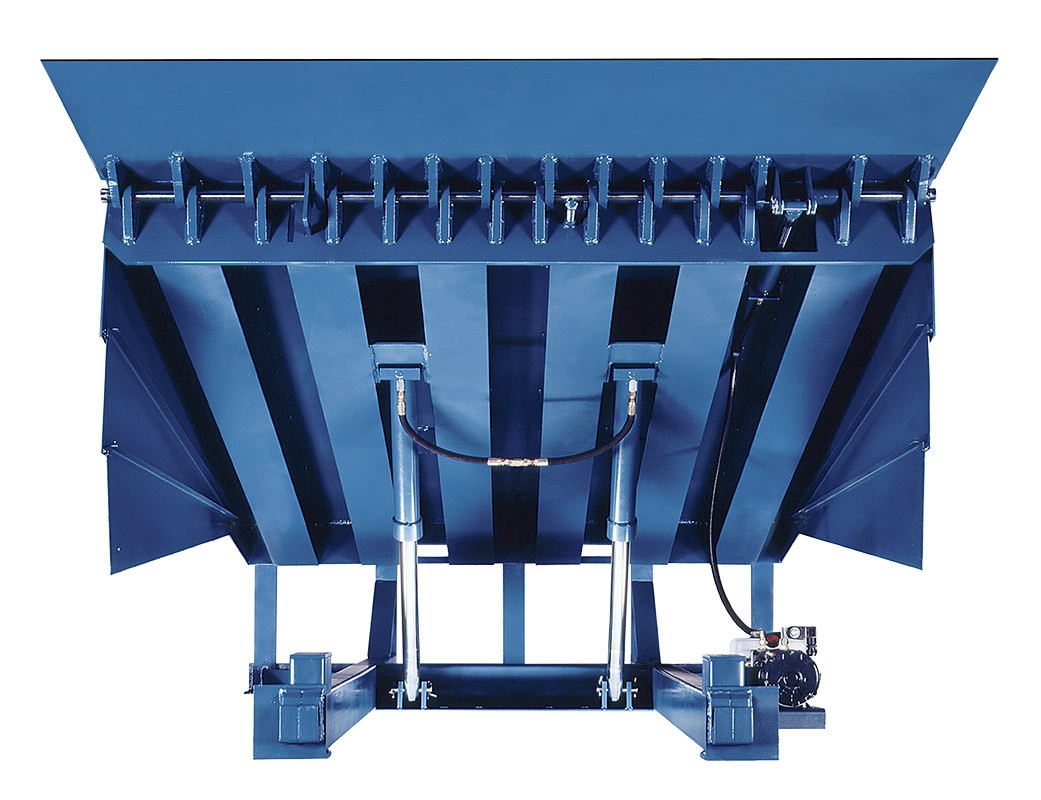

The platform is a unitized welded structure with continuous welds at the beam, header plate and lugs for maximum strength.

Beams are welded to the deck plate on both sides in a superior 33% weld pattern along their full length.

The deck plate, lip plate, beam sections and lugs are constructed of minimum 55,000-PSI yield material.

The continuous rear hinge with stainless steel rod provides 4″ side- to-side tilt with no pinch point and comes factory coated with anti- seize lubricant.

High visibility 4″ high side run-off guards are welded to each side of the ramp assembly.

A mechanical safety latch supports the ramp in its vertical stored position.

The front and rear hinge rods are SAE-1045 material, zinc plated and factory coated with anti-seize lubricant.

ELECTRICAL

External wall or stand-mounted totally enclosed non-ventilated 1.5 HP power unit available in all voltages.

NEMA 12 dust tight control panel with motor starter, push button controls, emergency stop and operator instructions on hinged cover.

HYDRAULICS

Hydraulic cylinders are a heavy-duty design with polished chrome rods, guide bearings and high-pressure seals.

The hydraulic hoses are SAE-100R2 with permanent fittings attached.

SYSTEM INTEGRATION

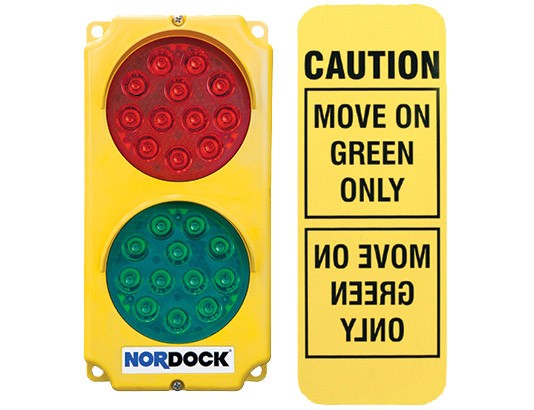

Various equipment integration systems are available to provide a safe sequence of operation.

The dock leveler, door, vehicle restraint, air seal and communication lights should all be integrated to ensure an optimum safety system.

WARRANTY

NORDOCK® guarantees the COLDSTORAGE™ Series hydraulic dock levelers will perform as described and to the full satisfaction of the purchaser for one-year from date of receipt.

In addition, under specified guidelines a 10-year structural and 20-year hinge warranty are included.

Consult your NORDOCK® representative for assistance in choosing the correct capacity and options for your application.