Description

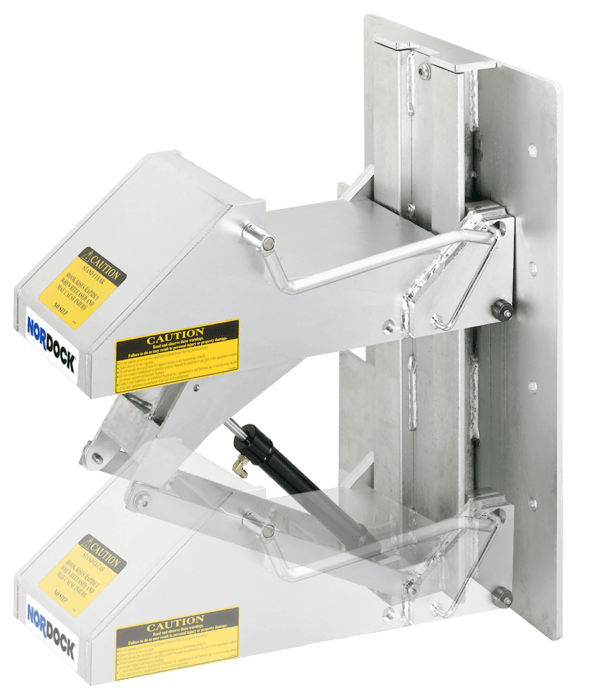

The ATL Automatic TRUCK-LOCK® Series of non-impact vehicle restraint uses a large barrier to safely engage and secure a trailer’s rear impact guard (RIG) to the loading dock with 32,000 lbs. of restraining force and mounting forces in excess of 100,000 lbs.

The ATL model of TRUCK-LOCK® is an automatic unit that activates and stores the spring-loaded HYDRA-FLOAT™ barrier via push button control.

When the barrier is activated, it can safely secure virtually all types of rear impact guards up to 30” above grade, automatically adjusting to trailer movement while maintaining positive contact with the RIG at all times.

The low-profile housing/barrier keeps working components safe from inclement weather and stores at 9″ above grade to keep free of snow, ice and debris and avoid potential damage from low hanging rear impact guards.

TRUCK-LOCK® models ATL-450 and ATL-900 come standard with a barrier-mounted sensor bar that provides positive communication to the operator when rear impact guard has been safely engaged.

Model ATL-450 Series Features & Benefits

- Non-Impact Design

- Barrier Store 9” High to Escape Impact from Low Rear Impact Guards

- HYDRA-FLOAT™ Barrier Automatically Adjusts to Truck Movement During Loading

- Vertical Locking Hook Secures Virtually All Rear Impact Guards with Excess of 32,000 lb. Restraining Force

- Simple Push Button Operation

- NEMA 12 Panel Enclosure

- All Weather Zinc Plated Components for Superior Durability

- Vertical Operating Range from 9” to 30”

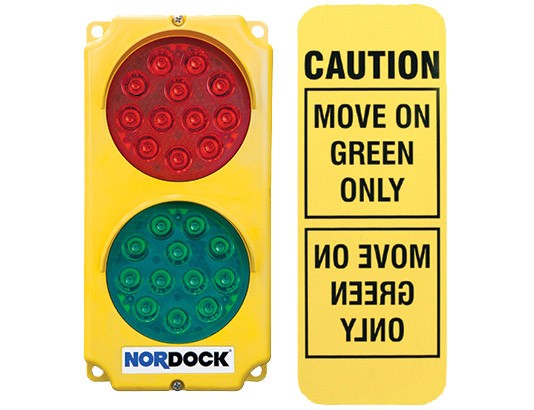

- High Visibility Inside & Outside LED Communication Lights and Signs

- Limited 5-Year Structural Warranty

- Virtually No Required Maintenance

- Housing Encloses Working Parts From Inclement Weather and Debris

- Self-Cleaning Guide Track

- Mounting Force in Excess of 100,000 lb.

- Barrier Mounted Sensor Communicates Positive Lock Position

- Dock Leveler Interconnect

Model ATL-900 Series Features & Benefits

- Non-Impact Design

- Simple Push Button Operation

- Barrier Store 9” High to Escape Impact from Low Rear Impact Guards

- HYDRA-FLOAT ™ Barrier Automatically Adjusts to Various Truck Heights

- Vertical Locking Hook Secures Virtually All Rear Impact Guards with Excess of 32,000 lb. Restraining Force

- Vertical Operating Range from 9” to 30”

- Easy to Install

- Barrier Sensor with Alarm Communicates Positive Lock Position

- Stored Down Switch

- Dock Leveler Interconnect

- Safety Stop Run Time Monitor

- Drive Down System with Obstruction Reverse Senso

- PLC Controller

- NEMA 12 Panel Enclosure

- All Weather Zinc Plated Components for Superior Durability

- Vertical Operating Range from 9” to 30”

- High Visibility Inside & Outside LED Communication Lights and Signs

- Limited 5-Year Structural Warranty

- Virtually No Required Maintenance

- Housing Encloses Working Parts from Inclement Weather and Debris

- Self-Cleaning Guide Track

- Mounting Force in Excess of 100,00 lbs.

ATL Options & Accessories

- Cantilever Extension Mounting Bracket

- Cast-In Mounting Plate

- Integrated Control Panel

- Keyed Override Switch

- Keyed Override Switch

- Barrier Sensor – Use Model ATL-450

The TRUCK-LOCK® Series of vehicle restraints improves safety with strength, convenience and reliability.

The TRUCK-LOCK® Series is a premium automatic unit designed to secure a truck at the loading dock by engaging the rear impact guard with a large barrier.

The housing/barrier combination is stored down and clear of incoming trucks while protecting working parts from weather and debris.

A barrier mounted sensor provides positive communication that the rear impact guard is engaged.

The HYDRA-FLOAT™ barrier automatically adjusts to various truck heights and maintains position during loading.

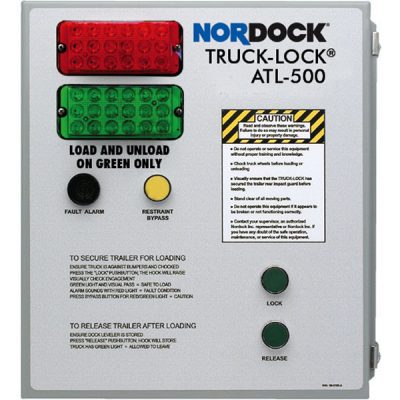

The operator easily activates and stores the barrier with a push of a button.

The low profile barrier stores at only 9″ high and raises to 30″ to restrain all types of trucks.

Construction

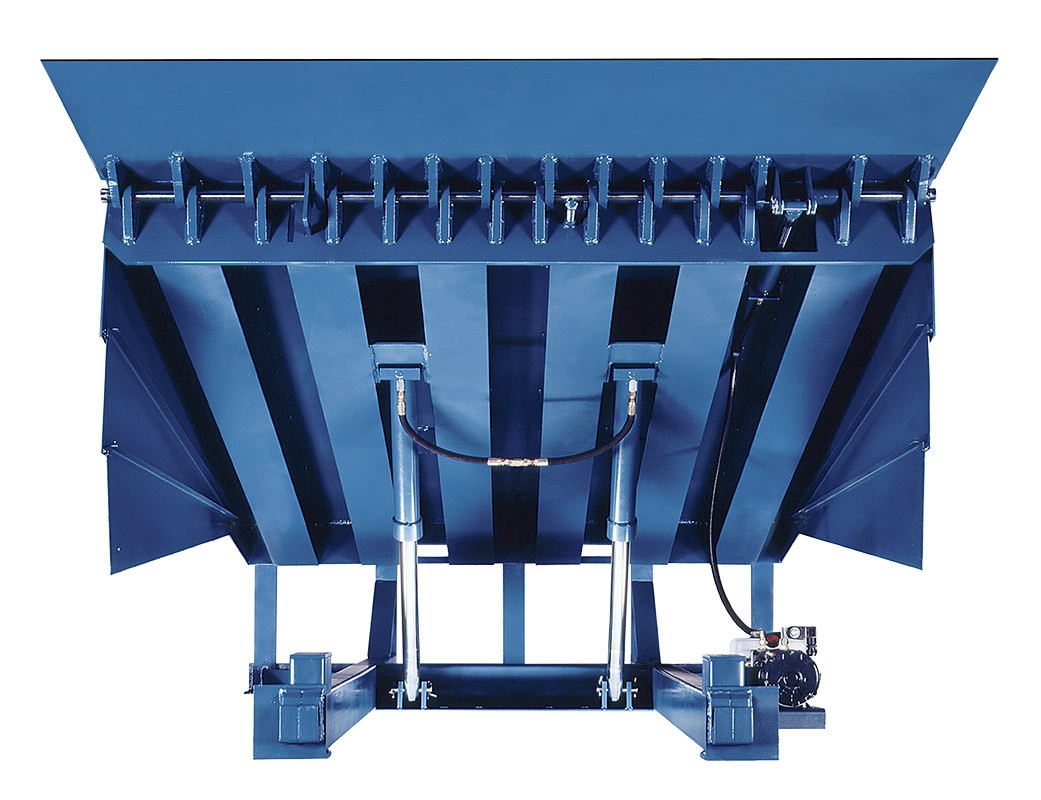

Enclosed barrier and housing design is a structural welded assembly constructed with dual reinforced 1/2″ steel restraining arms and a 1/4″ steel enclosure panel.

The housing protects components from the affects of weather, dirt and debris.

Dual 1/2″ steel reinforced vertical track is welded securely to a 3/8″ thick wall mounting plate.

All structural components including the mounting plate, track, barrier, and lift arms are zinc plated for high corrosion resistance.

The barrier is provided with black and yellow warning labels.

The control panel includes a power unit and solid state controls in a NEMA 12 enclosure with push buttons, alarm, operating instructions, and communication lights on the cover.

Power requirement is 120 VAC, 3 amps.

Operation

The trailer is backed into position at the loading dock until contact is made with the dock bumpers.

The driver then sets the brakes and chocks the wheels.

The dock attendant pushes a control button, activating the barrier that rises in the vertical track until contacting the rear impact guard and securing the trailer to the loading dock.

The barrier provides a restraining force in excess of 32,000 lbs. adjusting automatically to “trailer float” during loading and unloading ensuring trailer is fully restrained at all times.

The restraint monitors for abnormal conditions and will sound an alarm if the rear impact guard is not detected.

Pushing the override button will silence the alarm and provide a caution signal inside.

When loading/unloading is completed, attendant stores the barrier using the release button.

Installation

The NORDOCK® TRUCK-LOCK® vehicle restraints are factory assembled and tested.

The restraint is mounted to the dock face by means of concrete wedge anchors and welding to the pit curb angle.

An alternate method is to weld the restraint to a dock face embedded steel plate.

Total mounting force is in excess of 100,000 lbs..

Signs, control panel and optional components are installed in accordance to instructions provided in the owner’s manual.

Communication

Safety equipment includes flashing red or green inside and outside lights with operating instructions for the dock attendant, and an outside mounted sign with instructions for drivers

Warranty

One Year parts and labor warranty & Five Year structural warranty from date of shipment.

Warranties subject to limitations on liability.