Description

A powerful Hydraulic Leveler with a Safety Sliding Barrier-Lip

The FALL-SAFE™ SERIES SBL model features full hydraulic powered deck and lip functions controlled by a single pushbutton for easy-to-use operation. The barrier-lip in the stored position is designed to withstand a 10,000 lb., 4 mph forklift impact without failure.

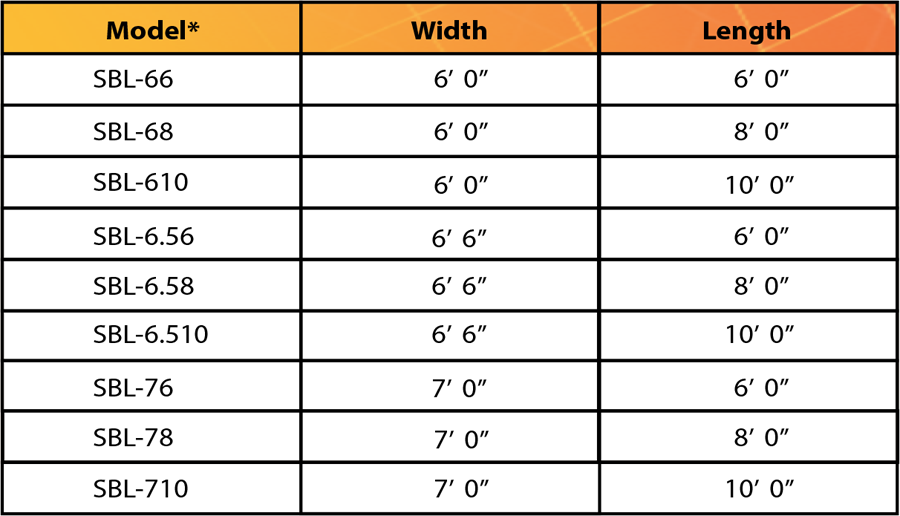

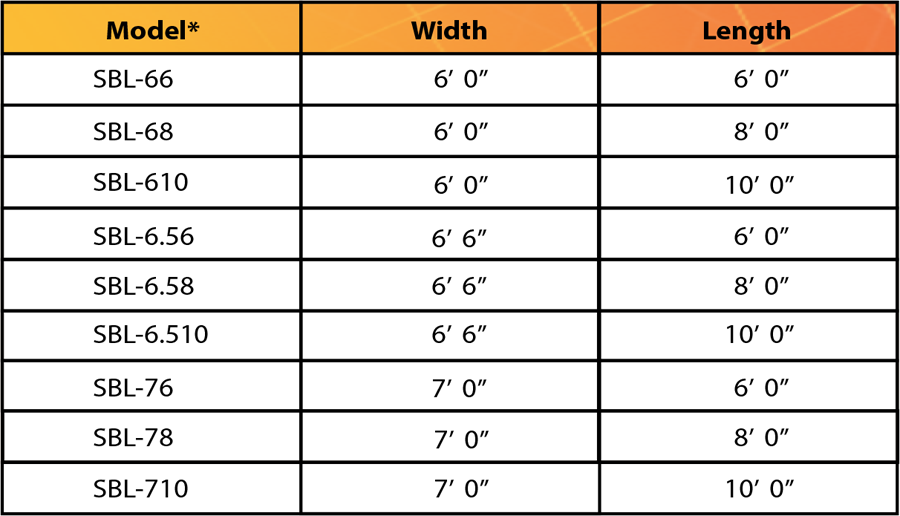

Available in 30,000, 40,000, 50,000, 60,000 and 80,000 lb. capacities and standard nominal sizes of 6′ wide x 6′ long to 7′ wide x 10′ long. Standard features include full operating range telescoping side guards, fall protection velocity fuse and a comprehensive warranty.

SBL Features & Benefits

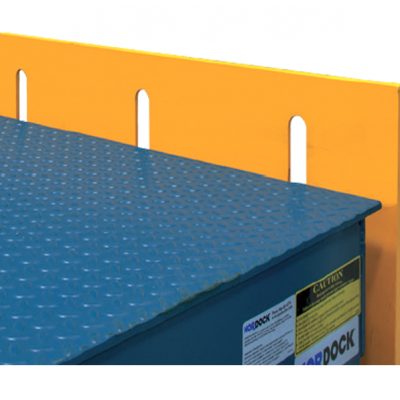

- Superior Patented Hinge Design Provides Protection from Accidental Falls off Vacant Docks

- 6″ High Safety Steel Barrier-Lip Withstands 10,000 lbs. of Impact at 4 MPH

- Sliding Lip can be Positioned Out of the Way to Allow Full Unobstructed Access to End Loads

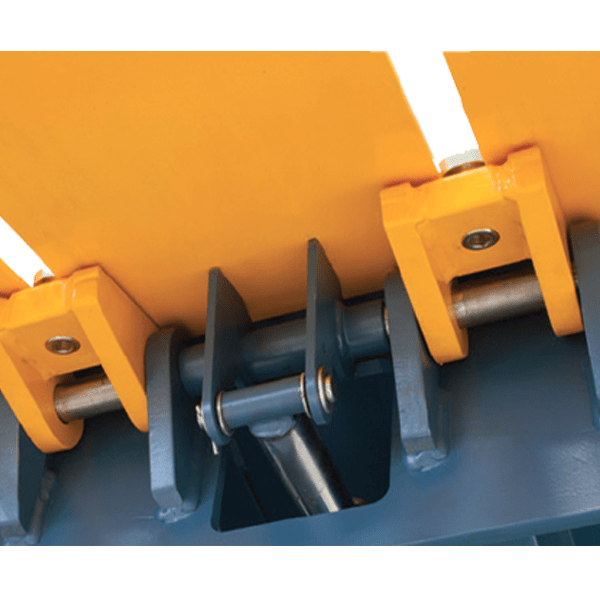

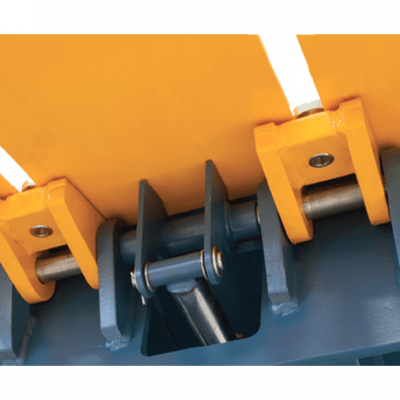

- Patented Self-Cleaning Open Lug & Sliding Front Hinge Design with Chrome Plated Rod

- Continuous Enclosed Rear Hinge with Zinc Coated Hinge Rod & 20-Year Warranty

- Heavy-Duty Lift Cylinder with Chrome Rod and Non-Adjustable Velocity Fuse

- Open Frame Design for Easy Pit Cleaning

- Full Operating Range Telescoping Side Guards

- Independent Deck Maintenance Support with Lock Out Tag Out Capability

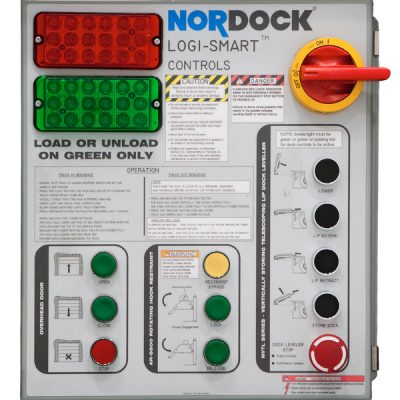

- NEMA 12 Dust Tight Control Panel

- Lip Extend and Emergency Stop Controls

- Two Laminated Dock Bumpers Included

SBL Additional Options & Accessories

- Self-Forming Pour in Pans & Curb Angle Sets

- Brush & ALL-SEAL™ Weather Seal Systems

- Foam Insulated Deck

- Spray Zinc Deck, Lip & Frame

- Loading Dock Lights

- IMPACT™ Series Steel Spring & Steel Face Dock Bumpers (10-Year Structural Warranty)

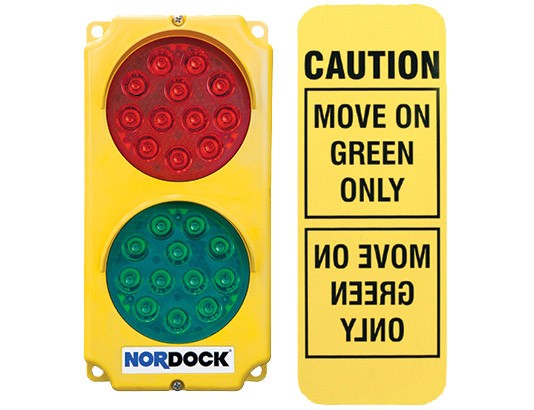

- LOGI-SMART® Integrated Control Systems

- SMART-HOOK® & TRUCK-LOCK® Vehicle Restraints

- Wheel Based & PIT-HOOK™ Vehicle Restraints

- WEARTOUGH® Dock Seals & Shelters

*Add capacity required from 30,000 to 80,000 Ibs. Example: SBL-68-50.

Description

The SLIDING BARRIER-LIP with its patented design is a hydraulic dock leveler that provides strength, reliability, and increased safety thanks to its automatic positioning sliding barrier-lip that prevents accidental falls off vacant docks. The FALL-SAFE™ SERIES MODEL SBL features full hydraulic powered deck and lip functions controlled by a single push button for easy-to-use operation. The stored barrier-lip is designed to withstand an impact from a 10,000 lb. forklift travelling at up to 4 mph.

Available in 30,000, 40,000, 50,000, 60,000, and 80,000 lb. capacities and standard nominal sizes of 6’ wide x 6’ long to 7’ wide x 10’ long. Standard features include full operating range telescoping side guards, fall protection velocity fuse and a comprehensive warranty.

Operation

The operator presses the ‘raise’ button until the deck is fully raised and lip automatically extends, or is independently extended by pushing the lip extend control.

On releasing the button, the extended lip will descend onto the truck bed.

The standard 20″ long lip projects 15″ beyond a 4″ bumper to engage and float with truck bed during loading.

Emergency latching stop button provided to arrest deck movement when pressed.

To store the leveler, the operator presses the control button until the lip fully retracts.

Releasing the button lowers the deck into its stored position, automatically providing the 6″ run off barrier.

Barrier lip provides unobstructed end loading above and below floor level.

Construction

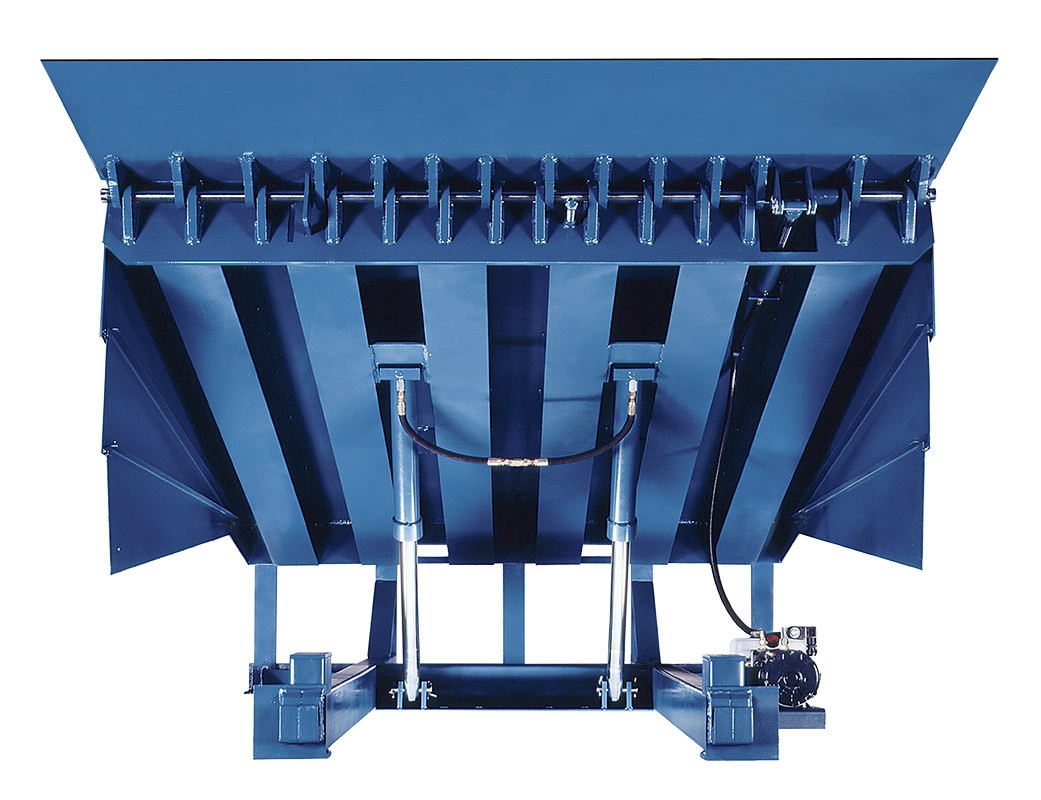

The platform is a unitized welded structure with continuous welds at the beams, header plate and lugs for maximum strength. The deck and lip plates are constructed of minimum 55,000-PSI yield material and the beams are 6” formed or structural beams with welded side guards to provide additional platform strength.

The continuous enclosed rear hinge provides 4” of side-to-side tilt with no pinch point and the frame has six solid steel rear supports and an open design for easy pit cleaning. Lip supports prevent illegal entry when the door is closed. Hard chrome front rod and zinc plated rear hinge rod, factory coated with anti-seize lubricant.

Electrical/Hydraulics

The power unit is a frame mounted integral assembly fully tested and oil filled.

The totally enclosed, non-ventilated 1 HP TENV motor is available in all voltages. Hydraulic hoses are SAE 100R2 with permanent fittings attached.

The hydraulic cylinders are a heavy duty design which polished chrome rods, guide bearings and high pressure seals.

Warranty

NORDOCK® guarantees that the FALL-SAFE™ Series SBL dock levelers will perform as described and to the full satisfaction of the purchaser for one year from date of receipt or NORDOCK® will either repair, replace or remove the product and refund the purchase price.

In addition, the front and rear hinge assemblies are guaranteed, under specified guidelines, for a period of 20-Years.

All NORDOCK® dock levelers are designed to exceed the safety and performance requirements of ANSI MH30.1 – 2007 and when properly applied comes with a 10-Year structural warranty and 5-Year Hydraulic.